For new operators, mastering a backhoe loader—with its dual functionality of front loading and rear digging—requires more than just learning basic controls. Safety is the foundation of efficient and accident-free operation: a single misstep can lead to equipment damage, workplace injuries, or even fatalities. Backhoe loaders are versatile workhorses in construction, landscaping, and municipal projects, but their complexity means new operators must avoid critical mistakes from day one. At SECUN, we prioritize operator safety, so we’ve compiled the most important safety taboos for new backhoe loader operators, plus how we support you in building safe habits.

1. Taboo 1: Skipping Pre-Operation Inspections

The biggest mistake new operators make is jumping into operation without checking the machine—this ignores hidden issues that can cause breakdowns or accidents mid-task.

What You Must Avoid:

Skipping fluid checks: Never overlook engine oil, hydraulic fluid, coolant, and fuel levels. Low hydraulic fluid can cause sudden loss of digging/loading power, while insufficient coolant leads to engine overheating.Ignoring tire/track conditions: For wheeled backhoe loaders, worn or underinflated tires reduce traction (risking slips on uneven ground); for tracked models, loose tracks can derail during operation.Neglecting safety components: Failing to test brakes, seatbelts, and backup alarms is a major risk. A faulty backup alarm means workers nearby won’t hear the machine, leading to collisions.

SECUN’s Tip:

Spend 5–10 minutes before each shift verifying fluids, tires, and safety features; our digital display also alerts you to low fluid levels or faulty components in real time.

2. Taboo 2: Overlooking Load Capacity & Stability

Backhoe loaders have strict load limits—exceeding them or ignoring stability rules is a top cause of tipping, one of the most dangerous accidents for new operators.

What You Must Avoid:

Overloading the front bucket: Never load more than the machine’s rated capacity (e.g., Front bucket capacity is 1.2 m³—exceeding this makes the front end heavy, causing the backhoe to tip forward). Digging too deep with the rear bucket: Digging beyond the recommended depth (usually 3–5 meters for mid-sized models) shifts the machine’s center of gravity backward, leading to rear tipping. Operating on uneven/sloped ground: Avoid working on slopes steeper than 15° (SECUN’s loaders have slope indicators in the cab). Turning or lifting loads on steep terrain drastically reduces stability.

SECUN’s Tip:

Our backhoe loaders include load weight sensors and slope alarms—if you exceed capacity or work on a too-steep slope, the machine sounds an alert and limits hydraulic power to prevent tipping.

3. Taboo 3: Ignoring Operator Position & Visibility

New operators often focus on controls and forget about their position in the cab or surrounding visibility—this leads to missed hazards (e.g., workers, obstacles) and incorrect operation.

What You Must Avoid:

Sitting incorrectly or not wearing a seatbelt: Slouching or leaning distorts your judgment of load balance; not buckling up means you could be thrown from the cab if the machine tips.Blocking blind spots: Never place tools, water bottles, or other items on the cab windows or mirrors—this blocks views of the rear digging area or front bucket. Operating without checking surroundings: Always walk around the machine before starting to clear obstacles (e.g., rocks, pipes) and ensure no workers are within 3 meters of the loader.

SECUN’s Tip:

SECUN backhoe loader cabs are designed for maximum visibility—with large windows, adjustable seats, and rearview cameras (standard on all 2025 models). The seatbelt also has a reminder alarm that won’t stop until it’s fastened, reinforcing safe habits.

For new backhoe loader operators, avoiding these taboos isn’t just about following rules—it’s about protecting yourself, your team, and your equipment. With SECUN’s safe, user-friendly machines and dedicated support, you’ll build confidence and master operation quickly.

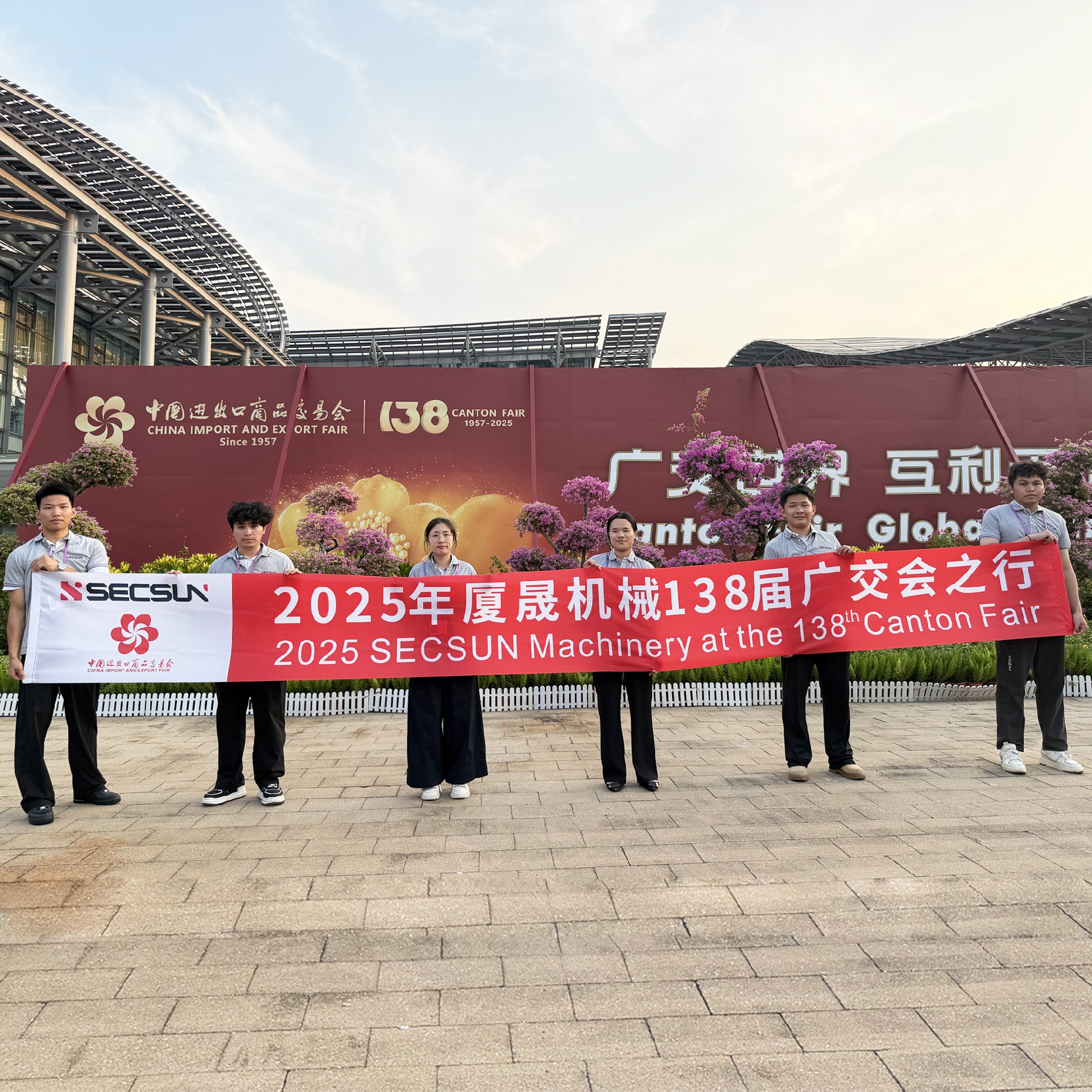

SECSUN Concludes a Successful Participation at the 138th Canton Fair: Forging Global Partnerships and Showcasing Machinery Excellence

SECSUN Concludes a Successful Participation at the 138th Canton Fair: Forging Global Partnerships and Showcasing Machinery Excellence

SECSUN Launches 18 Ton Wheel Excavator: A Powerhouse of Versatility and Efficiency

SECSUN Launches 18 Ton Wheel Excavator: A Powerhouse of Versatility and Efficiency

SECSUN Gears Up for the 138th Canton Fair: Unveiling Next-Gen Machinery Innovations

SECSUN Gears Up for the 138th Canton Fair: Unveiling Next-Gen Machinery Innovations

Telescopic forklifts Selection & Operation Guidelines: Make the Right Choice and Use It Safely

Telescopic forklifts Selection & Operation Guidelines: Make the Right Choice and Use It Safely