Scissor lifts are indispensable tools for aerial work—from warehouse inventory checks to construction site maintenance and municipal repairs. Their ability to lift workers and materials safely to heights makes them a staple in many industries. However, for both new and experienced operators, ignoring safety rules can turn these reliable machines into hazards: falls, tip-overs, or equipment malfunctions often stem from avoidable mistakes. At SECUN, we prioritize operator safety in every scissor lift we design, so we’ve compiled the most critical safety taboos to avoid—ensuring your aerial work stays efficient and accident-free.

1. Taboo 1: Exceeding Load Capacity or Misloading

Scissor lifts have strict weight limits—exceeding them or placing loads incorrectly is the top cause of tip-overs and platform failures.

What You Must Avoid:

Overloading the platform: Never exceed the rated load. Overloading bends the scissor arms, leading to sudden collapse.

Placing loads unevenly: Don’t stack heavy tools or materials on one side of the platform. Uneven weight shifts the lift’s center of gravity, making it prone to tipping, even on flat ground.

Standing on platform edges or guardrails: Never lean over guardrails to reach farther or stand on the platform’s edge—this puts you outside the lift’s safe zone and increases fall risk.

SECUN’s Solution:

Our scissor lifts feature built-in overload sensors that sound an alarm and lock the lift if weight exceeds the limit. They also has a non-slip platform surface and raised guardrails to prevent slips and falls, plus load distribution markers to guide proper material placement.

2. Taboo 2: Operating in Unsafe Environments

Scissor lifts are not designed for all conditions—ignoring environmental risks (like wind, slopes, or electrical hazards) endangers both the operator and the machine.

What You Must Avoid:

Using on steep slopes: Scissor lifts need level ground (maximum 5° slope) to stay stable. Operating on steeper terrain causes the base to shift, leading to tip-overs. Working near power lines: Keep the lift and platform at least 6 meters away from live power lines. Even indirect contact can cause electric shock—never use metal tools near power sources while on the lift.

SECUN’s Solution:

SECUN’s Products includes slope sensors that lock the lift if it’s on uneven ground, plus non-conductive platform options for work near electricity. We also provide a “weather safety guide” with each lift, outlining safe operating conditions for rain, wind, and extreme temperatures.

3. Taboo 3: Skipping Operator Training

Even if you’ve used other aerial equipment (like boom lifts), scissor lifts have unique safety rules—“learning on the job” is a dangerous mistake.

What You Must Avoid:

Operating without certification: Never use a scissor lift without formal training. You need to understand load limits, environmental risks, and emergency protocols—certification ensures this. Ignoring machine-specific training: Each scissor lift model has different capacities and features—don’t assume they work the same way.

SECUN’s Solution:

24/7 safety support: Our technical team is available anytime to answer safety questions (e.g., “Can I use the lift in rain?”) via phone or video call.

Operating a scissor lift safely isn’t just about following rules—it’s about protecting yourself, your team, and your business. By avoiding these taboos and using SECUN’s safety-focused lifts, you can tackle aerial tasks with confidence.

5 Key Factors to Consider When Buying a Skid Steer Loader

5 Key Factors to Consider When Buying a Skid Steer Loader

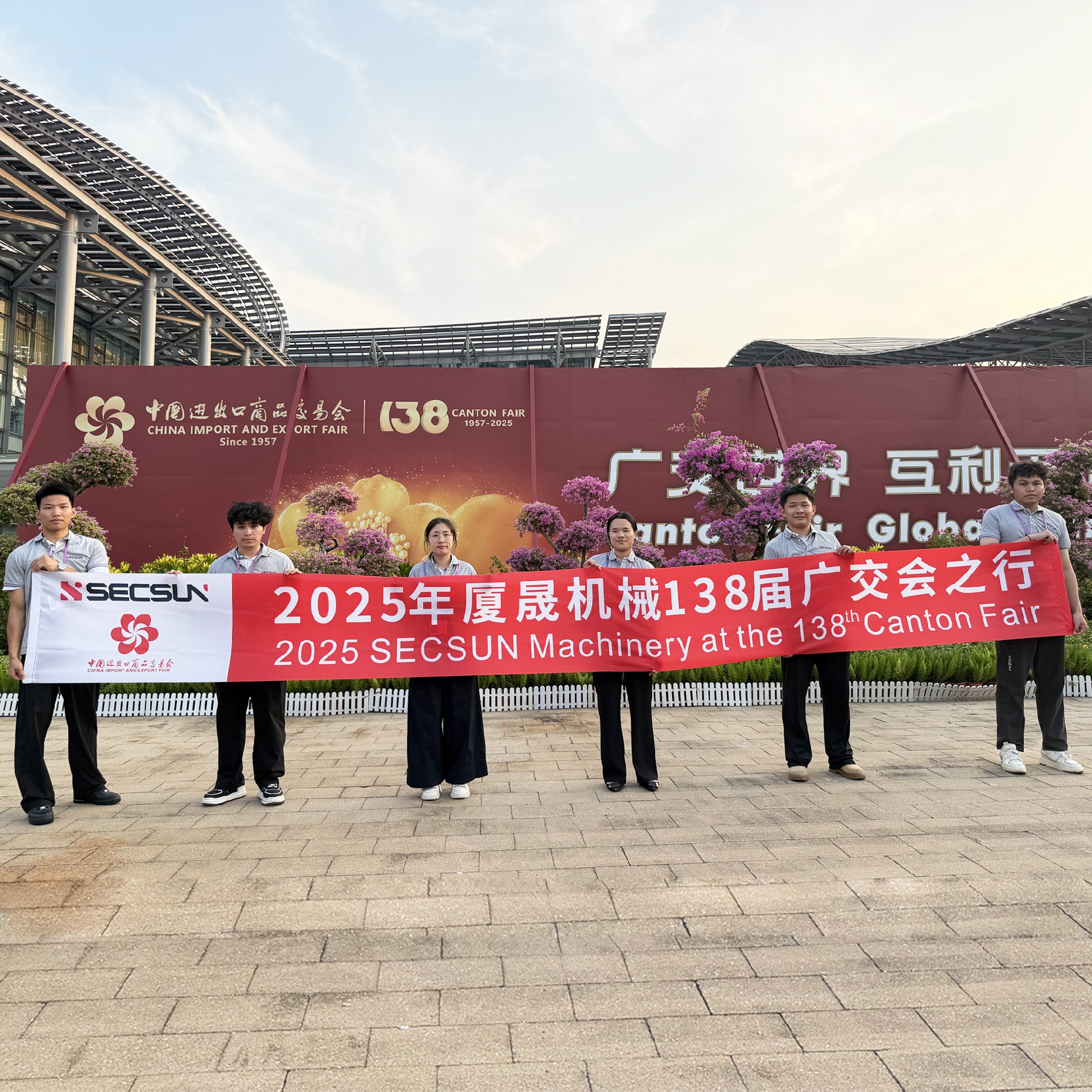

SECSUN Concludes a Successful Participation at the 138th Canton Fair: Forging Global Partnerships and Showcasing Machinery Excellence

SECSUN Concludes a Successful Participation at the 138th Canton Fair: Forging Global Partnerships and Showcasing Machinery Excellence

SECSUN Launches 18 Ton Wheel Excavator: A Powerhouse of Versatility and Efficiency

SECSUN Launches 18 Ton Wheel Excavator: A Powerhouse of Versatility and Efficiency

SECSUN Gears Up for the 138th Canton Fair: Unveiling Next-Gen Machinery Innovations

SECSUN Gears Up for the 138th Canton Fair: Unveiling Next-Gen Machinery Innovations